PRODUCTS

Characters of Mastication of Common Rubber

1: natural rubber

Natural rubber is easy to obtain plasticity. Constant viscosity and low viscosity standard maleic West pressure rubber have low initial viscosity and generally do not need to be plasticized. If the Mooney viscosity of other types of standard rubber is greater than 60, it still needs to be plasticized The roller temperature is 30 ℃ - 40 ℃, and the time is about 15-20min. When the temperature is above 120 ℃, the time is about 3-5min. When plasticizers or plasticizers are added, the plasticizing time can be significantly shortened and the plasticizing effect can be improved.

2: styrene butadiene rubber

Generally speaking, the Mooney viscosity of SBR is between 35-60. Therefore, styrene butadiene rubber can not be plasticized. But in fact, after plasticizing, the dispersibility of the admixture can be improved and the product quality can be improved. Especially for sponge rubber products, SBR is easy to foam after being plasticized, and the bubble hole size is even.

3: polybutadiene rubber

Cis-1,4-polybutadiene rubber has cold fluidity, which is not easy to improve the plasticizing effect. At present, the Mooney viscosity of common cis-1,4-polybutadiene rubber has been controlled in a proper range (45 ° ± 5 °) during polymerization. Therefore, it is generally not necessary to plasticize to directly mix.

4: Neoprene

Generally, the chloroprene rubber does not need to be plasticized, but due to the large toughness of the rubber, the thin pass of the open mill is used 3-5 times before mixing, which is helpful for operation. The thin pass temperature is generally 30 ℃ - 40 ℃, too high and easy to stick the roller.

5: ethylene propylene rubber

Because the main chain of ethylene propylene rubber is saturated structure, it is difficult to break down the molecule in the plasticizing process. Therefore, it is advisable to make it have suitable Mooney viscosity by synthesis without plastic refining.

6: butyl rubber

Because of its stable chemical structure, soft, small molecular weight and high fluidity, butyl rubber has little mechanical plasticizing effect. Generally, butyl rubber with low Mooney viscosity can be directly mixed without being plasticized. Butyl rubber with high Mooney viscosity can be plasticized by high temperature chemical method.

7: NBR

NBR has small plasticity, large toughness and large heat generation during plastic processing. Therefore, it is usually used in the open mill at low temperature (below 40 ℃), small roll spacing (about 1 mm), low capacity (70% of natural rubber) and staged plastic processing, which can achieve better results. NBR should not be molded by internal mixer. Soft NBR has a certain plasticity (generally less than 60 °), so it can be directly mixed without plastic refining.

- Prev:Notes of Impact Bed Installation

- Next:No;

-

On-site training. More insight into the applications, more development.

2019-10-19 -

Safety is no small matter. Make safety your first thought and take precautions from tiny things.

2019-10-19 -

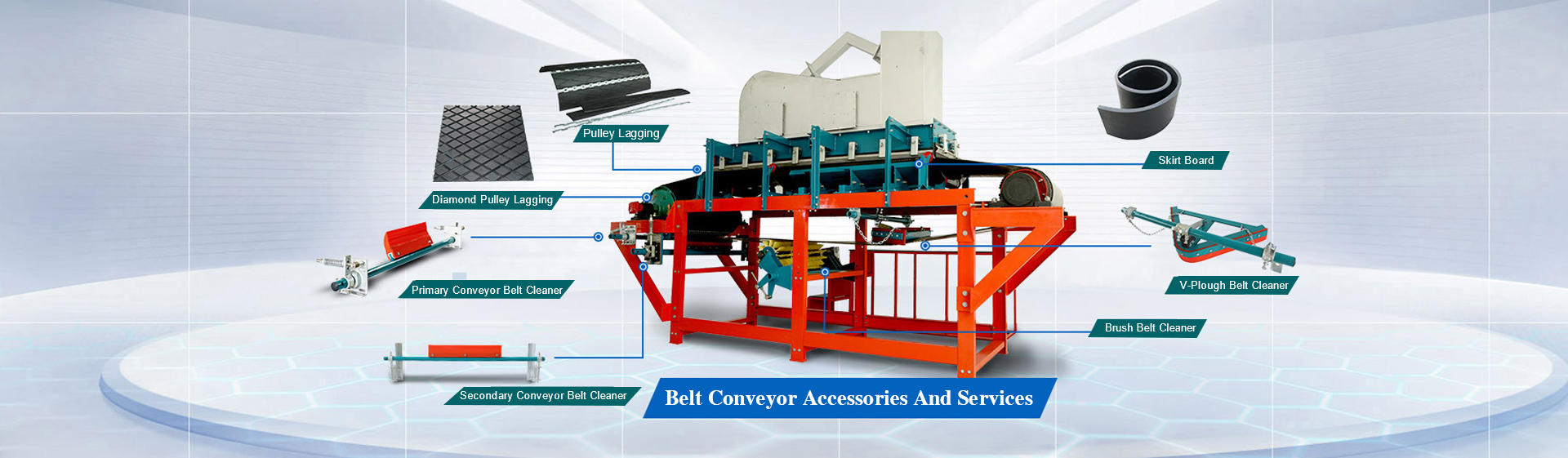

What Is Pulley Lagging

2019-10-21 -

Introduction of Pulley Lagging Installation Procedures

2019-10-21 -

Factors Affecting Wear Resistance of Pulley Lagging

2019-10-21 -

Advantages of Pulley Lagging

2019-10-21 -

Introduction of Wear Liners

2019-10-21

-

Significant Features of Wear Resistant Compound Steel Wear Plate

2019-10-21 -

Introduction of Conveyor Skirt Board and How to Install it

2019-10-21 -

Introduction of Belt Cleaner

2019-10-21 -

Features and Types of Belt Cleaners

2019-10-21 -

Introduction of Impact Bed

2019-10-21 -

Advantages of Impact Bed

2019-10-21 -

Design of Impact bed

2019-10-21